Milltronics offers a wide range of Vertical Machining Centers including Tool Room Mills, General Purpose VM Series Vertical Machining Centers, Performance XP Series Vertical Machining Centers, and Performance IL Series Vertical Machining Centers.

Tool Room Mills

Tool Room Mills are very flexible and can be used for a wide variety of different parts.

VK4II

- Travel (X, Y, Z): 33″ x 14.25″ x 5.8″

- Spindle: 40 taper, 4,000rpm

- Solid box way construction

- Rapids: 300ipm

TRM3016

- Travel (X, Y, Z): 30″ x 16″ x 20″

- Spindle: 40 taper BIG-PLUS, 8,000rpm

- Tools: 16 tool carousel ATC

- Rapids: 700ipm

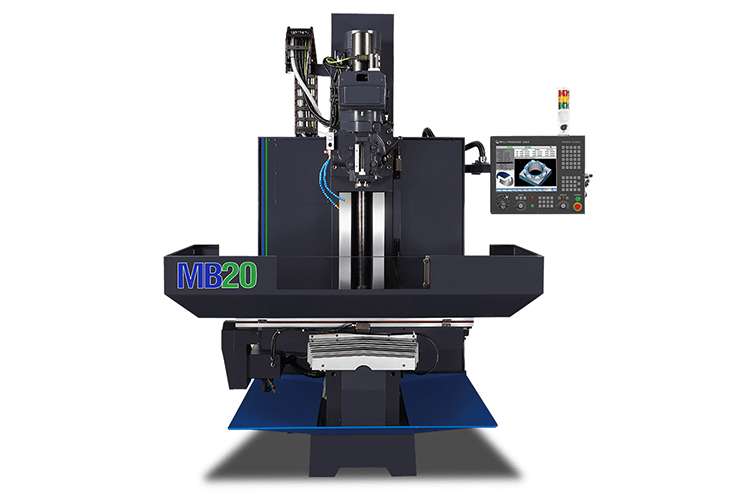

MB20

- Travel (X, Y, Z): 40″ x 20″ x 24″ and 6″ quill

- Spindle: 40 taper, 4,000rpm

- Rapids: 500/300ipm

- Solid box way construction

TRM20

- Travel (X, Y, Z): 40″ x 20″ x 24″

- Spindle: 40 taper, 8,000rpm

- Tools: 24 tool carousel ATC (opt. tool changer)

- Rapids: 500ipm

RH20-II

- Travel (X, Y, Z): 40″ x 20″ x 24″

- Spindle: 40 taper, 8,000rpm

- Tools: 24 tool carousel ATC

- Rapids: 500/300ipm

VM-Series

The VM Series machines are belt-driven and include standard features such as full enclosures, swing-arm tool changers, dual contact spindles, the 9000 Series control, and more.

VM2515

- Travel (X, Y, Z): 25″ x 15″ x 20″

- Spindle: 40 taper BIG-PLUS, 10,000rpm

- Tools: 20 pocket double arm ATC

- Rapids: 945ipm

VM3018

- Travel (X, Y, Z): 30″ x 18″ x 20″

- Spindle: 40 taper BIG-PLUS, 10,000rpm

- Tools: 20 pocket double arm ATC

- Rapids: 945ipm

VM4020

- Travel (X, Y, Z): 40″ x 20″ x 20″

- Spindle: 40 taper BIG-PLUS, 10,000rpm

- Tools: 20 pocket double arm ATC

- Rapids: 945ipm

VM5020

- Travel (X, Y, Z): 50″ x 20″ x 20″

- Spindle: 40 taper BIG-PLUS, 10,000rpm

- Tools: 20 pocket double arm ATC

- Rapids: 945ipm

VM5020EZ

- Travel (X, Y, Z): 50″ x 20″ x 20″

- Build with extra Z-clearance

- Spindle: 40 taper BIG-PLUS, 10,000rpm

- Tools: 20 pocket double arm ATC

- Rapids: 945ipm

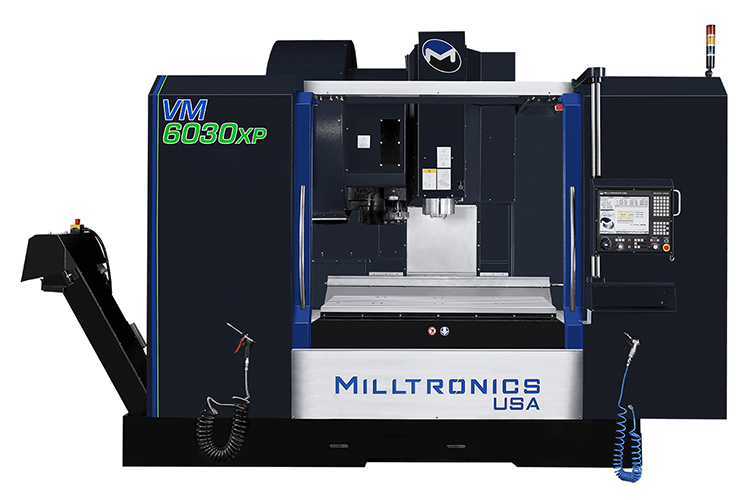

XP-Series

The XP stands for extra power since these CNC machines are built with a 50 taper spindle and linear cross roller guides for rigidity, direct-coupled ball screws for faster response, and dual wound spindle motors for faster acceleration / deceleration.

VM5025XP

- Travel (X, Y, Z): 50″ x 25″ x 24″

- Spindle: 50 taper BIG-PLUS, 8,000rpm

- Tools: 30 pocket double arm ATC

- Rapid Feed: 1,000/787ipm

VM6030XP

- Travel (X, Y, Z): 60″ x 30″ x 24″

- Spindle: 50 taper BIG-PLUS, 8,000rpm

- Tools: 30 pocket double arm ATC

- Rapid Feed: 1,000/787ipm

VM8434XP

- Travel (X, Y, Z): 84″ x 34″ x 30″

- Spindle: 50 taper BIG-PLUS, 8,000rpm

- Tools: 32 pocket double arm ATC

- Rapid Feed: 709/530ipm

IL-Series

The IL stands for inline since this series of vertical machining centers is equipped with a 40-taper BIG-PLUS® dual-contact inline spindle.

VM3018IL

- Travel (X, Y, Z): 30″ x 18″ x 22″

- Spindle: 40 taper BIG-PLUS, 12,000rpm

- Tools: 30 pocket double arm ATC

- Rapid Feed: 1,200/1,000ipm

VM4222IL

- Travel (X, Y, Z): 42″ x 22″ x 24″

- Spindle: 40 taper BIG-PLUS, 12,000rpm

- Tools: 30 pocket double arm ATC

- Rapid Feed: 1,200/1,000ipm

VM5025IL

- Travel (X, Y, Z): 50″ x 25″ x 24″

- Spindle: 40 taper BIG-PLUS, 10,000rpm

- Tools: 30 pocket double arm ATC

- Rapid Feed: 1,000/787ipm

VM6030IL

- Travel (X, Y, Z): 60″ x 30″ x 24″

- Spindle: 40 taper BIG-PLUS, 12,000rpm

- Tools: 30 pocket double arm ATC

- Rapid Feed: 1,000/787ipm