Measurement accuracy and repeatability are crucial aspects of any manufacturing QC endeavor, as they determine the reliability and trustworthiness of the results obtained. Several factors can influence the accuracy and repeatability of measurements, and it is important to understand and address each to ensure the validity of the data.

First, instrument calibration plays a vital role in measurement accuracy. Regular calibration is necessary to verify the accuracy of instruments and adjust them if needed. Any miscalibration can lead to systematic errors and introduce biases into the measurements.

Environmental conditions also have an impact. Variations in temperature, humidity, and pressure can affect the properties of both the object being measured and the measuring instruments. It is crucial to control and monitor these conditions to minimize, or compensate for, their influence on the measurements.

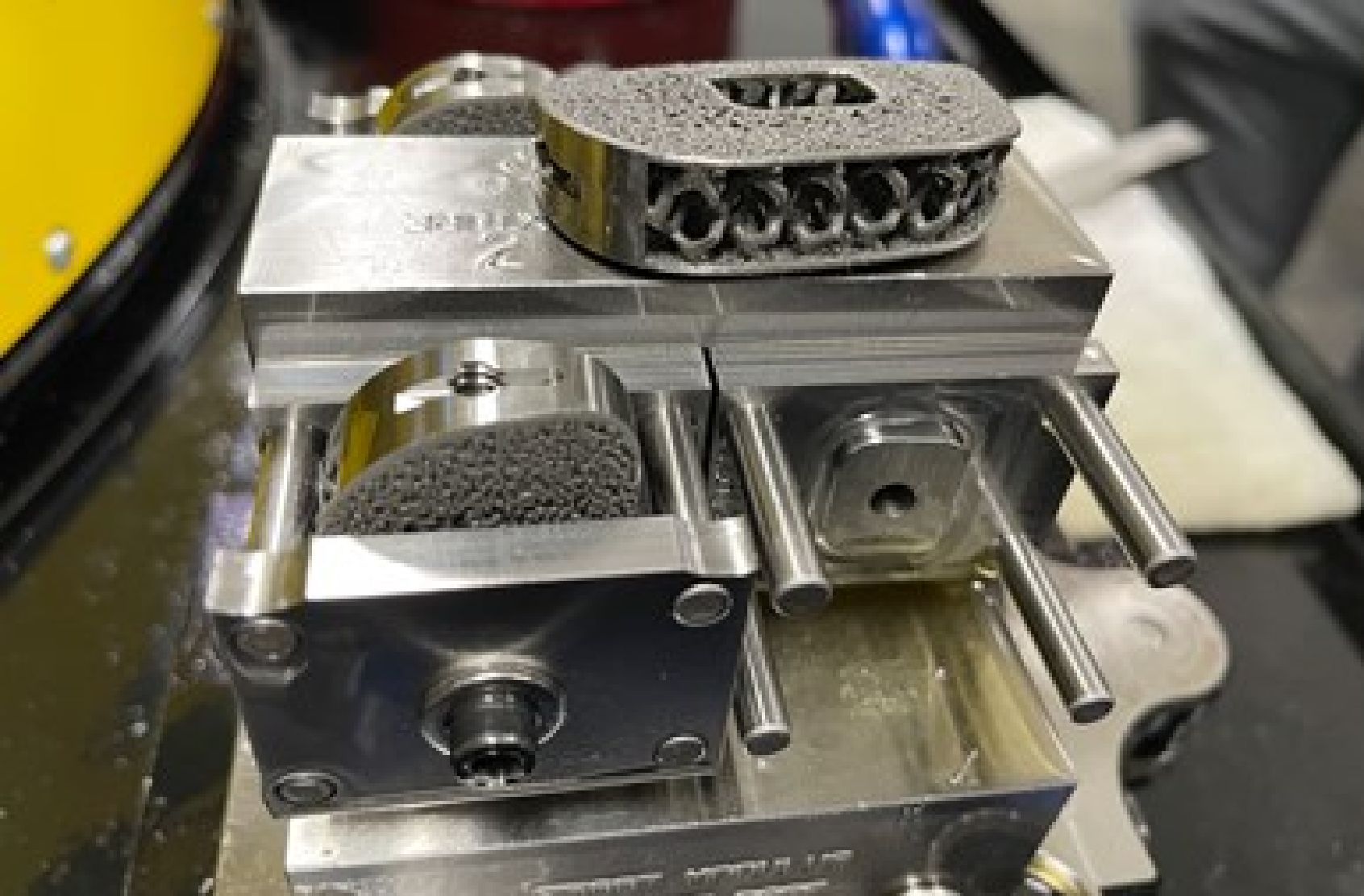

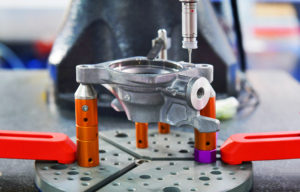

Part fixturing plays a crucial role in achieving accurate and repeatable results. This refers to the process of holding the object being measured in a stable and controlled position during the measurement process. It helps eliminate potential variations caused by part movement or misalignment, which can introduce errors and compromise measurement accuracy and repeatability. It minimizes the effects of human error by reducing the chances of accidental movement or misplacement of the part. Various techniques and tools can be employed for part fixturing, including jigs, clamps, vices, and specialized fixtures designed specifically for a particular measurement task. The choice of fixturing method depends on the nature of the object, its size, shape, and the specific requirements of the measurement process.

Human factors can also introduce error. Differences in operator experience, skill level, technique, and even their vision can influence the accuracy and repeatability of measurements. Proper training, standardized procedures, and careful attention to detail are necessary to minimize these errors.

Another influence is the presence of random errors, which occur due to inherent variability in the system or measurement process. They can be minimized by increasing the sample size, employing statistical techniques, and averaging multiple measurements.

In conclusion, measurement accuracy and repeatability are influenced by various factors, including instrument calibration, environmental conditions, part fixturing, human factors, and random errors. By understanding and mitigating these influences, quality control professionals can generate reliable and repeatable measurements to make informed decisions, validate designs, and ensure product quality.

Did you know Concept is an accredited calibration provider? ISO/IEC 17025:2017. Visit here to schedule a calibration or consultation now.